Home Products Industrial vacuum cleaner X9 Industrial Vacuum Cleaner

X9 Industrial Vacuum Cleaner

- Model : X9

Main Items

Specification

Power (kw)

11

Air volume (㎡/h)

1050

Suction force (m bar)

280

Weight (kg)

180

Voltage (V)

380

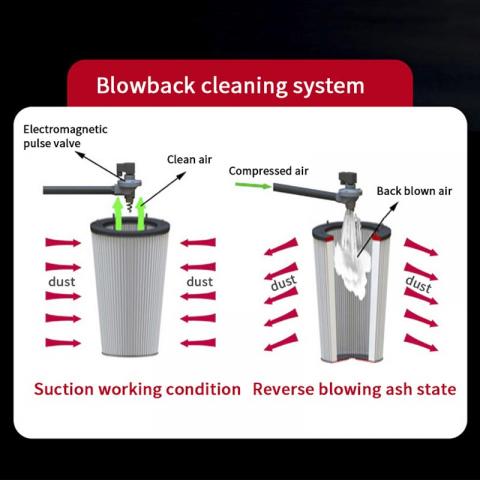

Ash cleaning method

pulse back blowing dust

Filtering Configuration

Polyester coated filter canister

Filtration accuracy (μm)

0.3

Filter area (cm²)

25000

Dust collecting bucket capacity (L)

100

Length of wire (m)

5 (can be extended)

Machine size (mm)

1450*630*1600

- Add To Inquiry

- Have a question?

- Share:

Product performance:

Core components:

1.Motor: equipped with 3600W motor.

Strong suction power comes from strong power;

Copper coils, dual air blades suction, dual-airway heat dissipation design, to achieve long-lasting motor work without heating;

Three levels of adjustable suction, to achieve deep cleaning;

2. Filter: triple filtration, including washable motor acoustic cotton, washable HEPA high-efficiency filter, washable anti-static coated fibre, to achieve 0.3 micron filtration effect;

Set up with filter element blowback cleaning function, one key automatic blowback, to ensure filter element permeability, to achieve the maximum efficiency of the machine;

3. Dust collection barrel: 100L stainless steel dust collection barrel, barrel wall thickness of 1.2mm;

Main components:

1. Quick-insert suction port, expanded air inlet, large particles will not be blocked;

2. Stainless steel frame with industrial heavy-duty casters, light to move, sturdy and durable;

3. Stainless steel silencer, effectively reduce the noise, provide a comfortable working environment;

4. Complete set of brush head accessories;

Safety settings:

1.Schneider electric control system, independent control, real-time monitoring;

2.Vacuum negative pressure system, timely reminder when the machine is clogged, shut down the machine at any time;

3. Aviation-grade plug, insulated flame retardant and splash-proof;

4. Electrostatic chain, export static electricity, exclude potential safety hazards;

5. Anti-static handle, to exclude hidden danger safe operation;

6. Pressure relief valve, to avoid filter blockage damage to the machine;

7. Cyclone dust removal system, to prevent filter blockage, reduce the filter load.

- X9 Industrial Vacuum Cleaner

- Add To Inquiry

- X8 Industrial Vacuum Cleaner

- Add To Inquiry

- X7 Industrial Vacuum Cleaner

- Add To Inquiry

- X6 Industrial Vacuum Cleaner

- Add To Inquiry

- X5 Industrial Vacuum Cleaner

- Add To Inquiry

- X3 Industrial Vacuum Cleaner

- Add To Inquiry

Subscribe for our latest Updates

Stay up to date with the latest news, announcement and articles.

- Contact Us

- No.1679, gaocheng rd., jin'an District, Lu'an City, Anhui,China

- +86-19056415571

- mike@ecohdr.com

- 008619056415571

- 008619056415571

- Products

- Floor Scrubber

- Floor Sweeper

- Industrial vacuum cleaner

- Vacuum cleaner

- Dust cart

- Aerial work platform

- News

- Company News

- Blogs

- About us

- About us

- Certification

- Culture

- FAQ

- 01@ecohdr.com

- 272399455

- 19966123358

- +86 0564-321027

中文站

中文站